The black badge

Mechanics of the Black Series

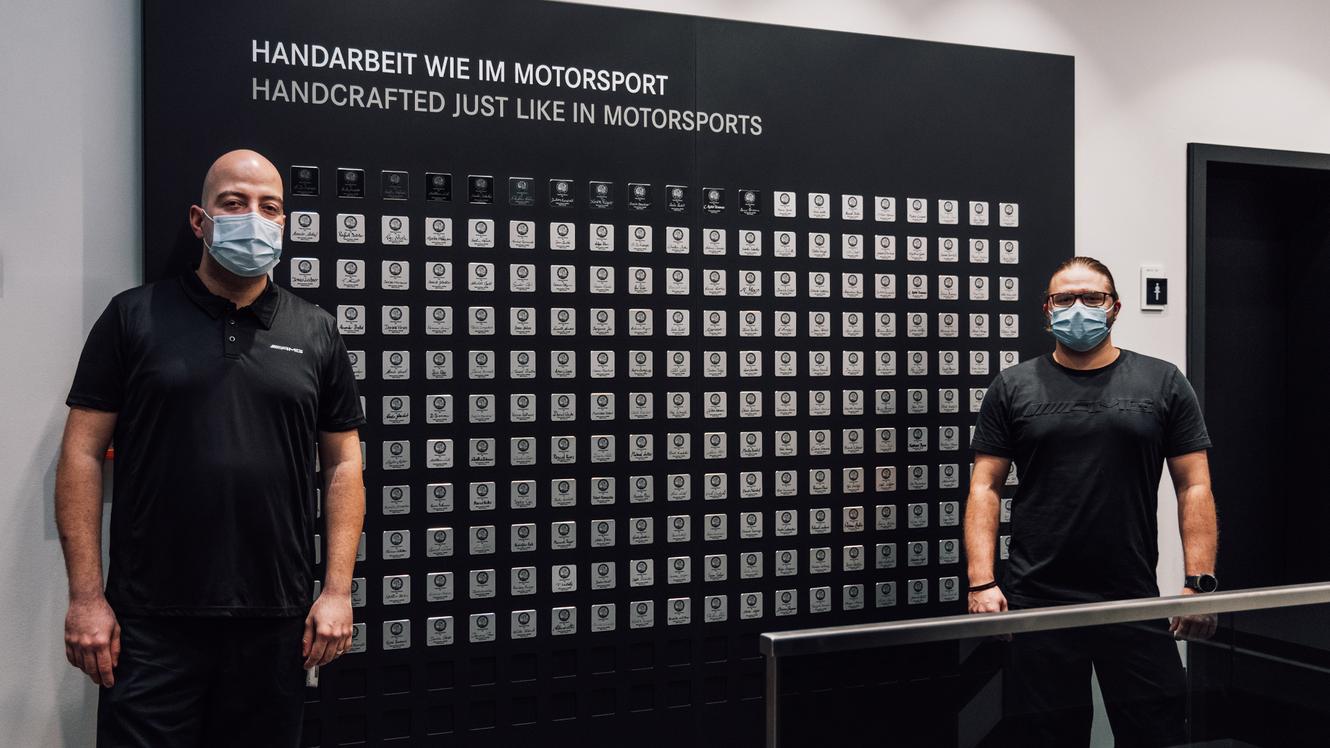

AMG shows the name badges of all current mechanics on the "Wall of Fame" in the engine manufacturing workshop. Most of the badges are silver in colour. Except for a few signatures against a black background right at the top of the wall.

These black badges stand for the most exclusive engines available from AMG: the Black Series engines. These are more powerful than normal series-production engines, are built using very specific components – the current engine of the Mercedes-AMG GT Black Series, for example, features a flat-plane crankshaft, different camshafts, and twin-scroll turbochargers, to name but a few parts.

All mechanics who build engines at AMG have been carefully selected. And thirteen of them have been appointed Black Series mechanics. They were chosen based on experience, and lots were drawn among those with equal qualifications.

Salih Denizer and Jannick Franzmann are in the Black Series squad. "This makes me incredibly proud", says Salih Denizer (41). "When I check the production schedule and see that I am building Black Series engines that day, my heart beats faster." Jannick Franzmann (28) nods: "And when you see such a car on the road you think to yourself 'the engine might have my name on it'. That is a very special feeling." Both become very enthusiastic whenever they talk about their job in general. Like all Black Series engine mechanics, they also build engines for "normal" AMG cars – to which they give the same passion and meticulous attention as well as a silver-coloured badge.

Both are ardent car enthusiasts for whom a dream came true when they started working for AMG years ago. "My first job was on the V12", Salih remembers. "When my supervisor showed me around on my first day and I saw just how clean everything is here, words failed me." Jannick first worked on the M156, the 6.2-litre naturally aspirated engine.

Now, he drives his own C 63 with that engine. He works as a floater, knowing how to build both four- and eight-cylinder engines, and has done additional training which enables him to operate the cold test benches, where the finished engines are checked.

Salih, too, owns one of his dream cars: a Mercedes-AMG C 43 which he bought from a fellow student at master craftsmen college. One day he would like to own a Mercedes-AMG E-Class sedan, from the W212 series which boasts the 6.2-litre engine. "Design, engine, sound – this car has it all", he says.

The two experienced car mechatronics have each built far more than 1,000 engines. For them, it was a point of honour to complete the training for this most powerful AMG engine of all times with the utmost precision and diligence. "On this engine not only many components are different but also some tools", explains Salih. Like his colleagues, he builds every single engine as though it was his own.

And like his fellow mechanics, Salih and Jannick enjoy meeting those people who drive their engines. "It is really great when customers show us photos of their cars, when you can see how happy they are. This is a special moment for us mechanics, too", says Jannick. He would like to know what customers feel when they buy a Black Series. "I cannot imagine that it is just an investment."

Chances are that he will be able to ask on of "his" Black Series customers that question. Currently, Covid-19 has put a temporary stop to the "meet and greet" during factory visits. But once the pandemic has abated, with a little luck customers will be able to meet mechanics again.

AMG Vehicles

The spot for exciting updates regarding our AMG models including walkarounds, technical backgrounds and first-hand information from our product experts.