New idea on the test bench

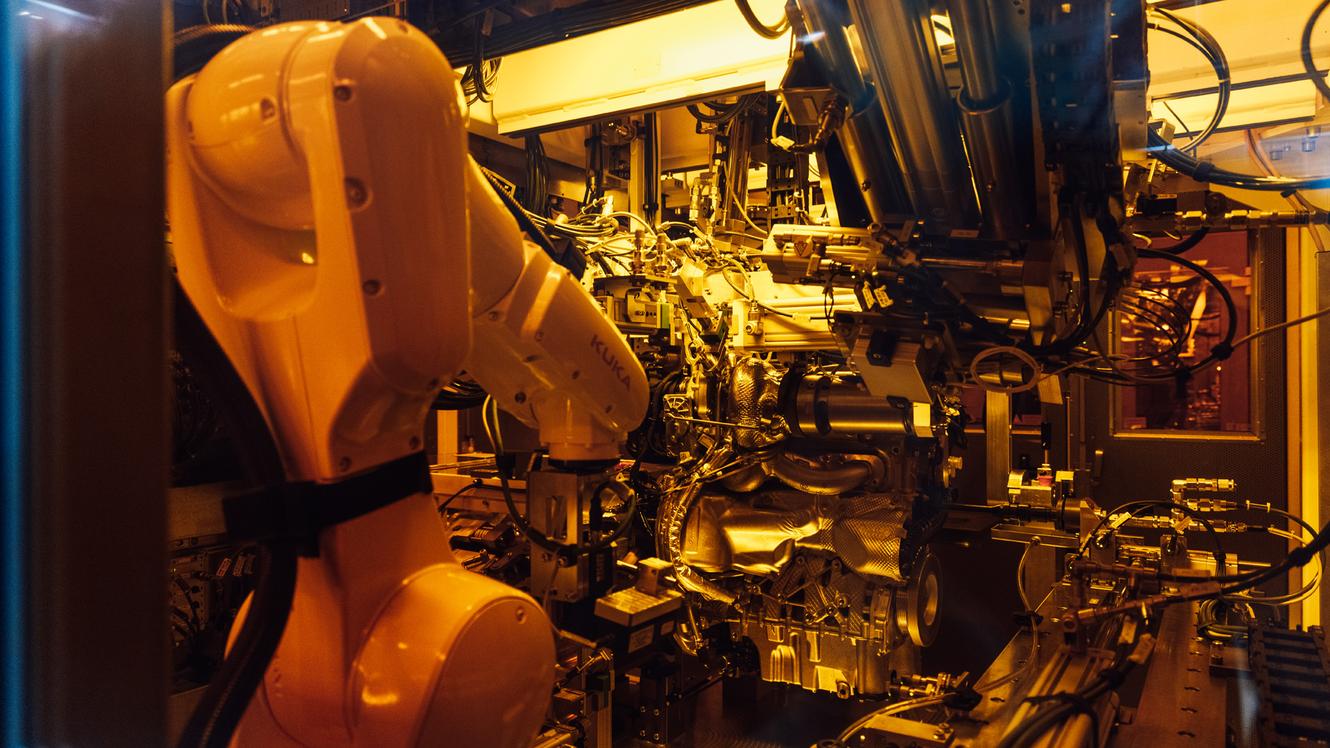

A robot in engine manufacturing

"Is my engine tested here, too?" is one of the questions that visitors to the engine manufacturing workshop in Affalterbach ask most frequently. Yes, is the simple answer, we test every single engine.

Those who expect red-hot turbochargers and manifolds in the process will have to think again.

"We specifically do not check our engines by injecting and combusting fuel", explains Alexander Messer, the measurement engineer in charge. "We use cold testing."

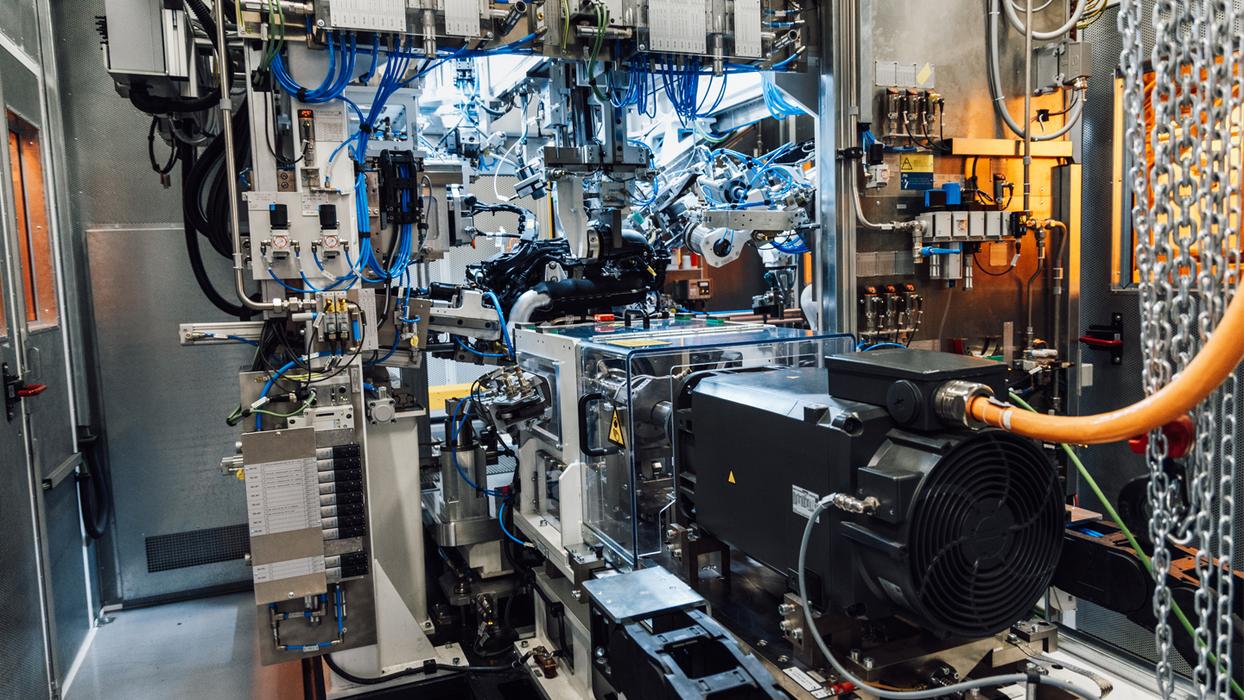

On these test benches, an electric motor rotates the engine's crankshaft, thus putting the "engine innards" in motion. This is more efficient. The test is completed faster and it is locally emission-free. By comparison with testing on a hot test bench, the cold tests at AMG save an impressive 2,800 tons of CO2 annually.

Efficiency is one thing. The cold tests are more conclusive, too. This is important because measurement engineers want to make sure that pressure levels, friction coefficients and vibrations are fine as well as all ducts and connections leak-free.

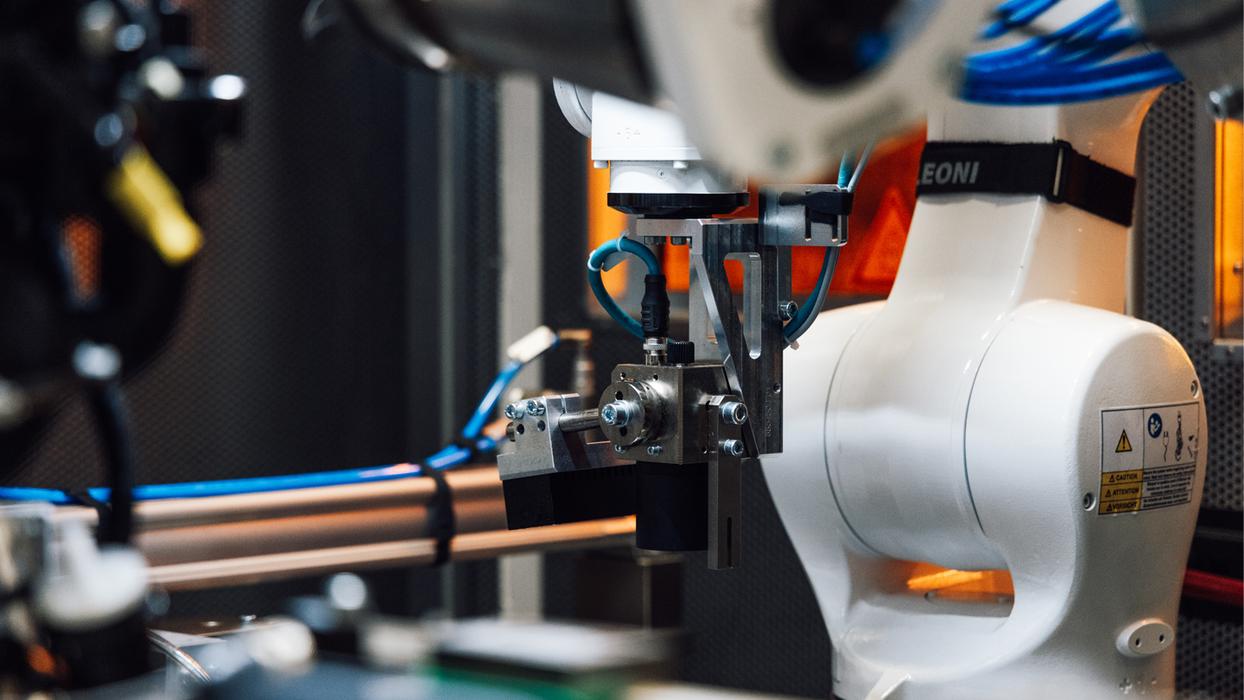

To ensure this, the cold test benches are fitted with numerous high-resolution sensors – and in the case of the four-cylinder test bench with a small robot. This latter uses a UV camera to check the turbocharger's oil ducts for leaks.

"Oil would fluoresce in UV light", explains Alexander Messer and adds with pride:

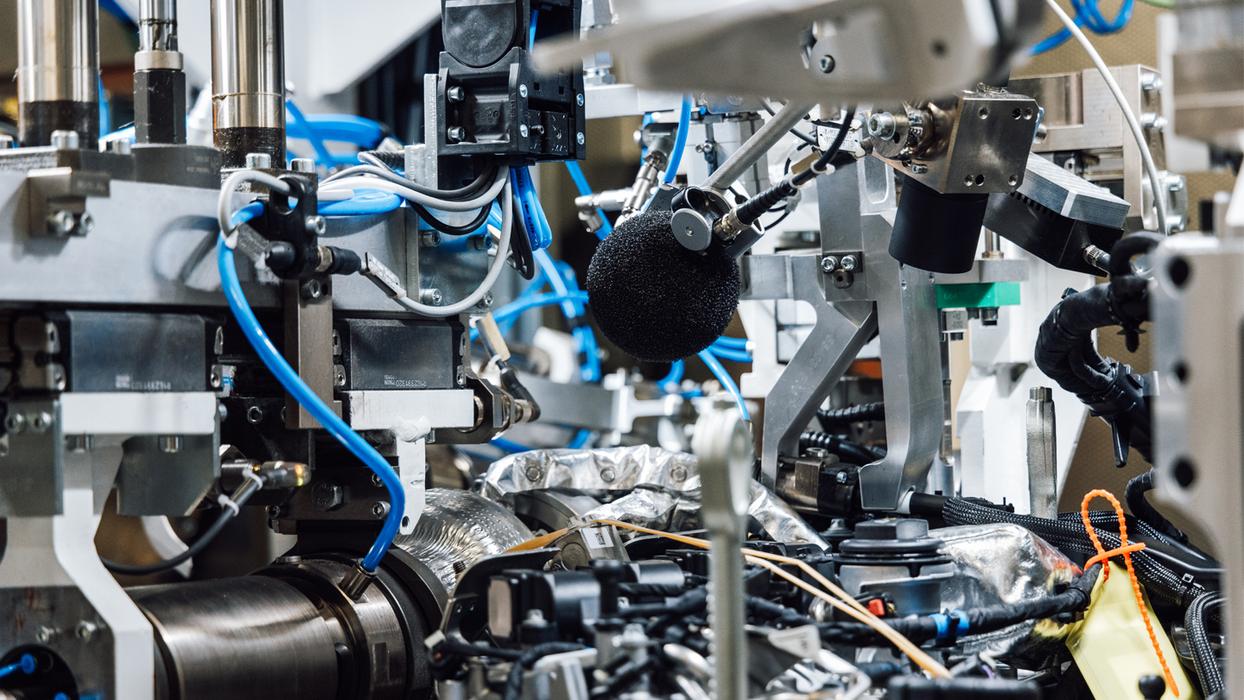

Advocates of hot testing will find that Messer takes the wind out of their sails by naming yet further advantages of the "cold benches": Right in the centre of the test bench, there are highly sensitive sensors and microphones which measure and record acoustics and vibrations – this is called NVH or "noise vibration harshness" in engineering jargon. This means that the test bench can hear and feel when an engine runs to perfection.

But during hot testing, engines produce such vibrations, too, don't they?

"Yes, of course", nods Alexander Messer. "But just you try to place a highly sensitive sensor close enough to a running combustion engine to collect useable data. Exhaust temperatures exceed 900 degrees Celsius. Sensors would not survive."

Despite this, the Affalterbach engine manufacturing workshop has hot test benches, too: They are used to measure the output of random samples of engines, thus confirming the test results from the cold test benches.