The AMG Driving Simulator

Welcome to the World of Vehicle Dynamics

These days it is possible to digitally simulate many vehicle responses and behaviours at an early stage. That said, graphs, images, and figures don't automatically align with subjective perception. Weighing various characteristics in different disciplines in order to find the best compromise is particularly difficult. It is incredibly helpful if you can put pilots in the vehicle to gauge their tactile feedback, thus pairing artificial with human intelligence.

This is where Michael Bidlingmaier and his team come in. They are responsible for the development of driving dynamics at AMG. In this phase, all components relevant to dynamics, such as body, drive train, chassis, tires and vehicle dynamics systems, are digitally evaluated and developed with regard to their function. They have built the driving simulator – the so-called DIM250 (Driver in Motion) – together with their partner company at the Affalterbach site. It consists of a brain with no less than 14 computers which are made up of the following components ...

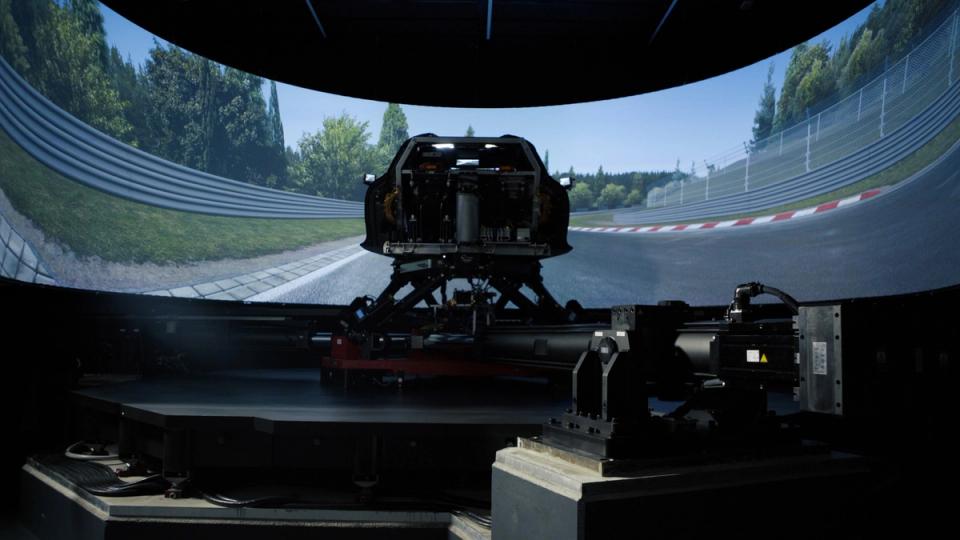

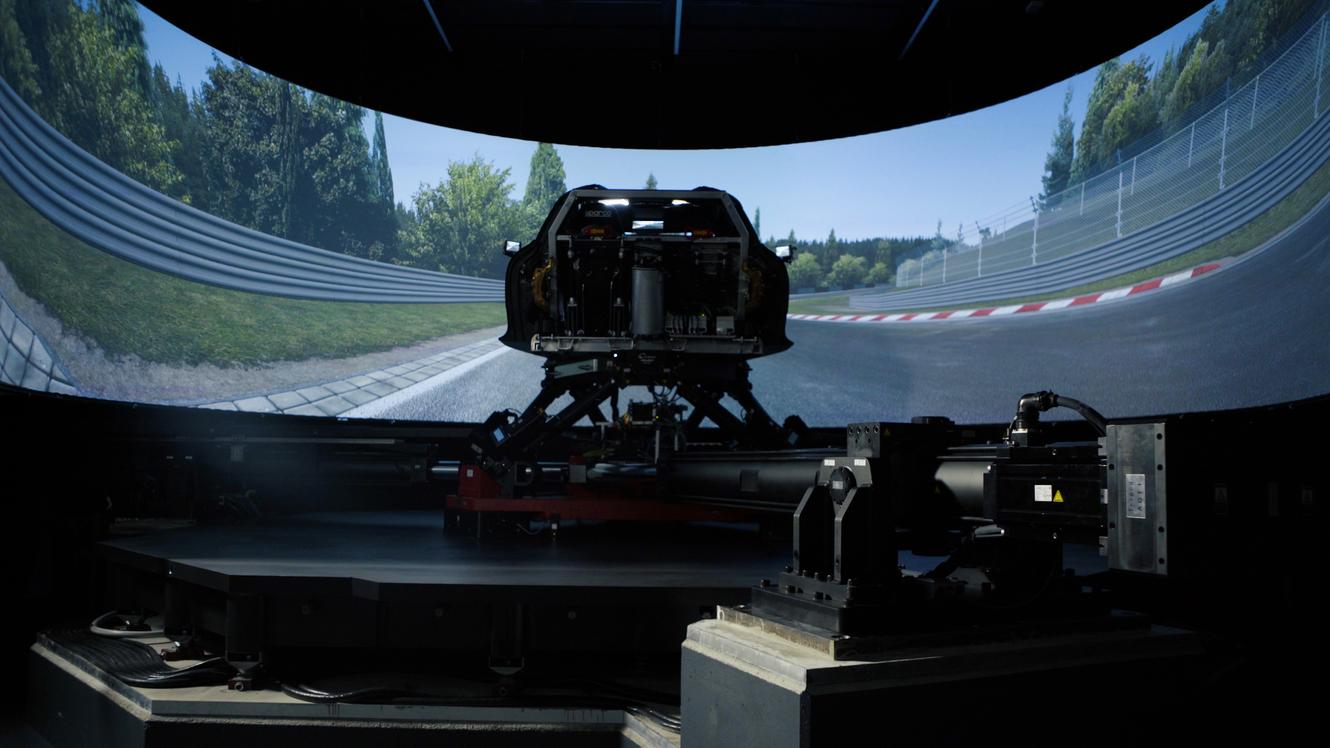

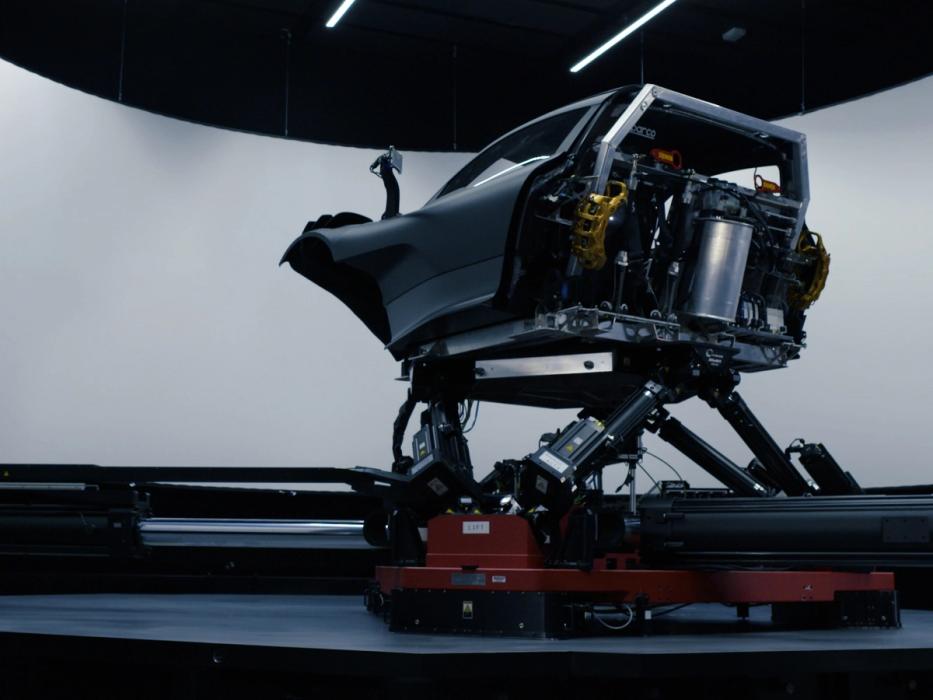

The foundation consists of approximately 65 tons of reinforced concrete. An extremely precisely aligned 5x5-meter steel plate, which weighs around 30 tons, is placed on top of it. The motion system consists of an air/steel mounted tripod, which is moved by three actuators. With these tripods, it is possible to move the platform side to side and up and down with approx. 1 G and to produce yaw movements, i.e. rotations around the vertical axis, at 165 degrees/s. On the tripod there is a hexapod. The six electronically-powered legs represent the highly dynamic movements in six degrees of freedom longitudinally, laterally, and vertically at 2.5-3 G; the three rotary movements wobble, yaw, and pitch at 2500-3500 degrees/s2.

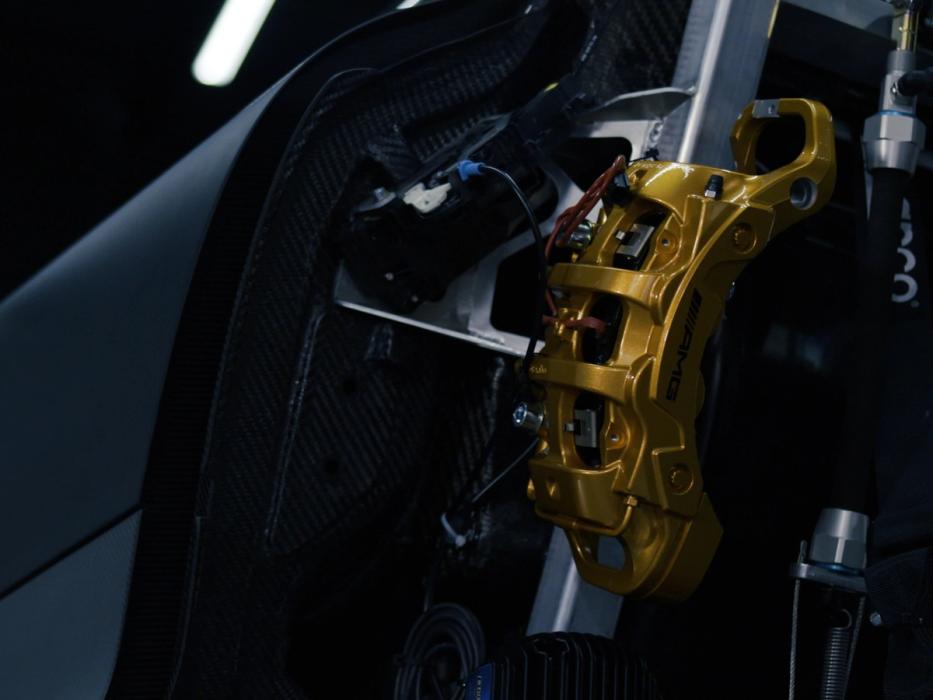

The passenger cabin of a vehicle sits on top of this apparatus. Its interior equipment includes several interfaces between driver and vehicle, such as radio, navigation, steering wheel, accelerator, and brake pedal. It is also equipped with a steering actuator, a complete braking system including ESP, sound system, screens in the rear-view mirrors, a five-post shaker for high-frequency road and engine vibrations, and active seat suspension. This is how we create an authentic driving experience.

The active AMG seat is equipped with inflatable air cushions and an active belt. It simulates the extended longitudinal and lateral forces (long braking zones or cornering) that cannot be produced by the motion system. A fixed, conical nine-metre, 260-degree screen with five high-end Barco projectors and laser phosphor 4K technology is used for visual imaging.

The physical model of the vehicle and its systems runs on a real-time machine in the "brain" of the driving simulator. Depending on the type of analysis we’re interested in, everything from basic concept data about the vehicle, such as engine/centre of gravity position, to full-scale system prompts, can be changed there at the push of a button.

Many important driving dynamics decisions that cannot be changed later -- at least not without great difficulty or expense -- are made at an early stage. It is therefore a huge advantage to get into the vehicle together with all the colleagues from the various departments involved in its development and to be able to digitally evaluate all possible solutions at the Nordschleife, on the Hockenheimring, or in everyday situations. This process means that every time a colleague steps into the simulator, it is a team performance in which the different perspectives of all individuals are optimally combined. Efficiency is the name of the game – from the beginning to the finished product, vehicles with more complex and better-networked systems can be produced in shorter model cycles.

Looking to get up close and personal with the simulator? Then be sure to check out our latest INSIDE AMG episode "K for Kinematics"! Our experts Michael, Sebastian, and Jan introduce Felix to the world of kinematics and driving dynamics.

New AMG ONE lap record

In this episode, join Performance Driver Maro Engel and the AMG ONE as they return to Nürburgring to attempt to break their own record as the fastest street-legal car on the track. With rain, pressure, and unexpected challenges at every turn, they push the boundaries of what’s possible.