CONCEPT AMG GT XX

With pioneering innovations for supreme sustained performance

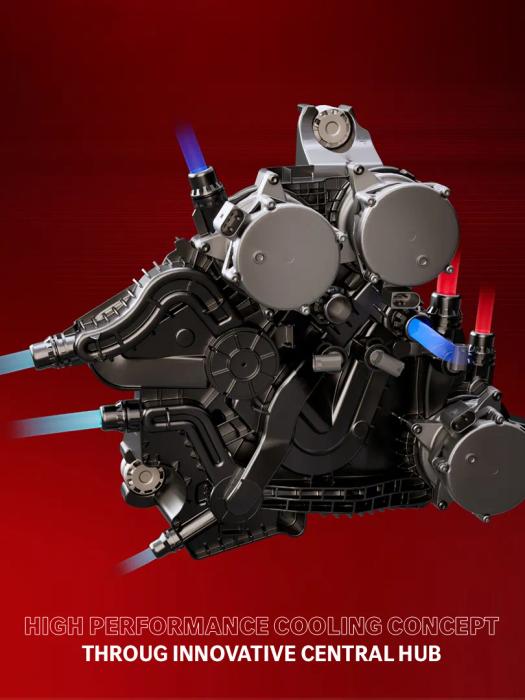

Groundbreaking cooling concept

Innovative Cooling with Central Cooling Hub

High-performance cooling is essential to delivering the sustained power of the CONCEPT AMG GT XX. At its core lies the innovative direct liquid cooling of the high-performance battery. Equally important, however, is the demand-based cooling of the Electric Drive Units (EDUs) on the front and rear axles, as well as the OneBox.

Each of these systems requires its own temperature ranges. For example, the EDUs operate within a different temperature range than the battery. The precise distribution of coolant to all components is handled by the so-called Central Coolant Hub (CCH). This highly integrated component is the “mastermind” of the cooling system in the CONCEPT AMG GT XX, designed to adapt to various scenarios.

The major advantage of this cooling system lies in its ability to deliver full performance in virtually all situations – whether driving under high load or at the charging station – thanks to its combination of axial-flux motors and directly cooled battery.

Unlike conventional electric vehicles, the system ensures maximum charging power even immediately after high-speed driving and at extreme ambient temperatures, such as those during the demanding endurance tests in Nardò. Conversely, after high-speed charging, full driving performance is instantly available.

The cooling concept of the CONCEPT AMG GT XX also includes a passive underbody cooling plate integrated at the front. Permanently flushed with coolant, this underbody plate helps to relieve the main radiator to such an extent that the air control system can remain closed over long periods. This improves energy efficiency and reduces aerodynamic drag.

Innovative user experience

Predictive Performance Manager and Augmented-Reality Helmet

A crucial factor in the success of the extreme test program in Nardò was the Predictive Performance Manager (PPM) – a specially developed software of the powertrain. It optimizes the energy flow and provides drivers with precise guidance for a particularly performance-efficient driving style, supporting the practical implementation of the strategy. Information is delivered acoustically and visually via signals on the instrument panel and through a dedicated Augmented-Reality helmet.

This AR technology was, for the first time, directly integrated into a racing helmet, becoming an additional, innovative element of the user experience. The helmet overlays situational vehicle and track data in real time into the driver’s field of vision, complementing the information shown on the in-car displays. This includes the battery charge level, speed, lap counter, and the function selected via the steering wheel buttons – allowing drivers to keep their eyes on the track more consistently.

Also displayed are speed-dependent colored lane indications in the form of arrows, particularly valuable during night driving. The start and end of recuperation phases were symbolized by augmented reality gates.

The helmet is designed to match the record vehicle, painted in Sunset beam orange, and features the AMG emblem on the back. It also integrates the motorsport-proven HANS (Head And Neck Support) safety system. Despite its AR equipment and integrated battery, it weighs only around two kilograms – remarkably light for this level of functionality.

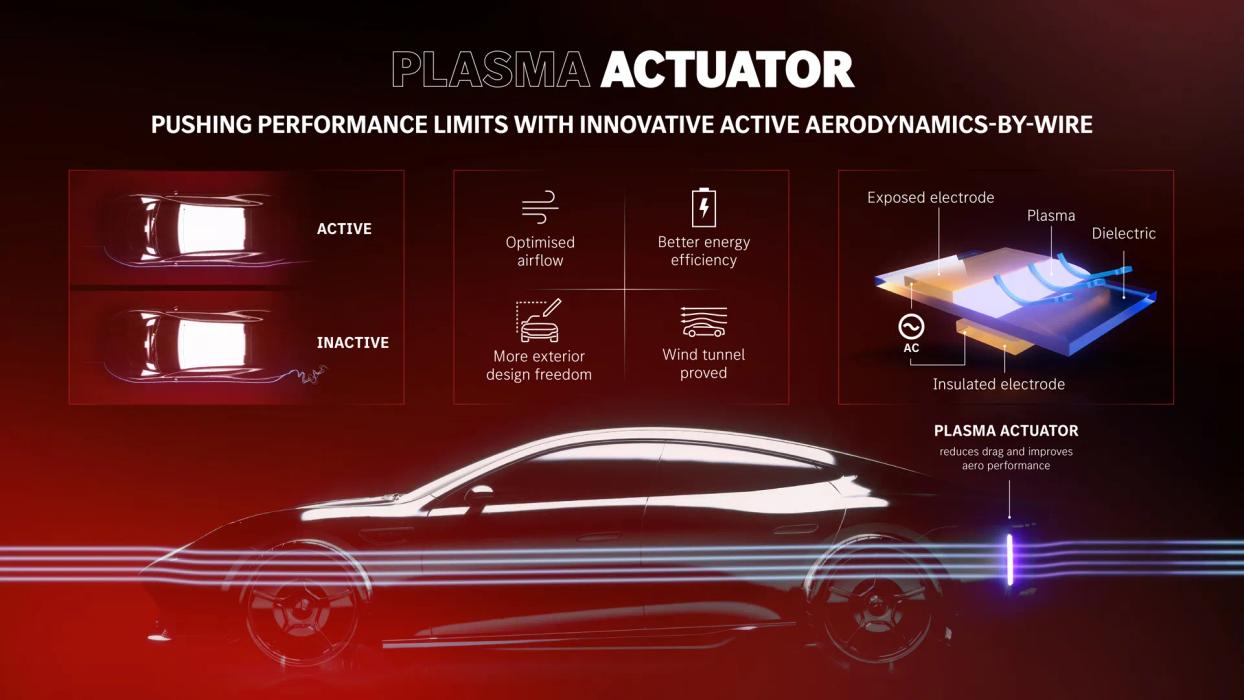

New design freedom

Active aerodynamic control of air flow with plasma actuators

Within the CONCEPT AMG GT XX technology program, research also focused on a fundamentally new technology: “Aerodynamics by wire.” Although not directly tied to the Nardò run, for the first time, the research team was able to use an electric plasma actuator to create a targeted flow separation on a body curve at the rear.

Normally, this requires a physical, geometric spoiler lip on the outside of the vehicle. This highly innovative solution reduces air resistance, improves aero performance, and opens entirely new design freedom. Proof of effectiveness was demonstrated on a 1:1 wind tunnel model of the CONCEPT AMG GT XX, with successful measurements recorded at speeds of up to 200 km/h.

The plasma actuator components are thin and light. They can be painted over, making them invisible in the vehicle’s overall appearance. Their design contributes to improved drag coefficients and energy efficiency. Plasma actuators also require no mechanical, hydraulic, or moving parts. They can be adapted quickly to different design drafts and easily built in different sizes and shapes.

Mercedes-Benz thus becomes the world’s first automobile manufacturer to successfully test this technology in such a setting – and will continue research to evaluate its potential for future applications in vehicles.

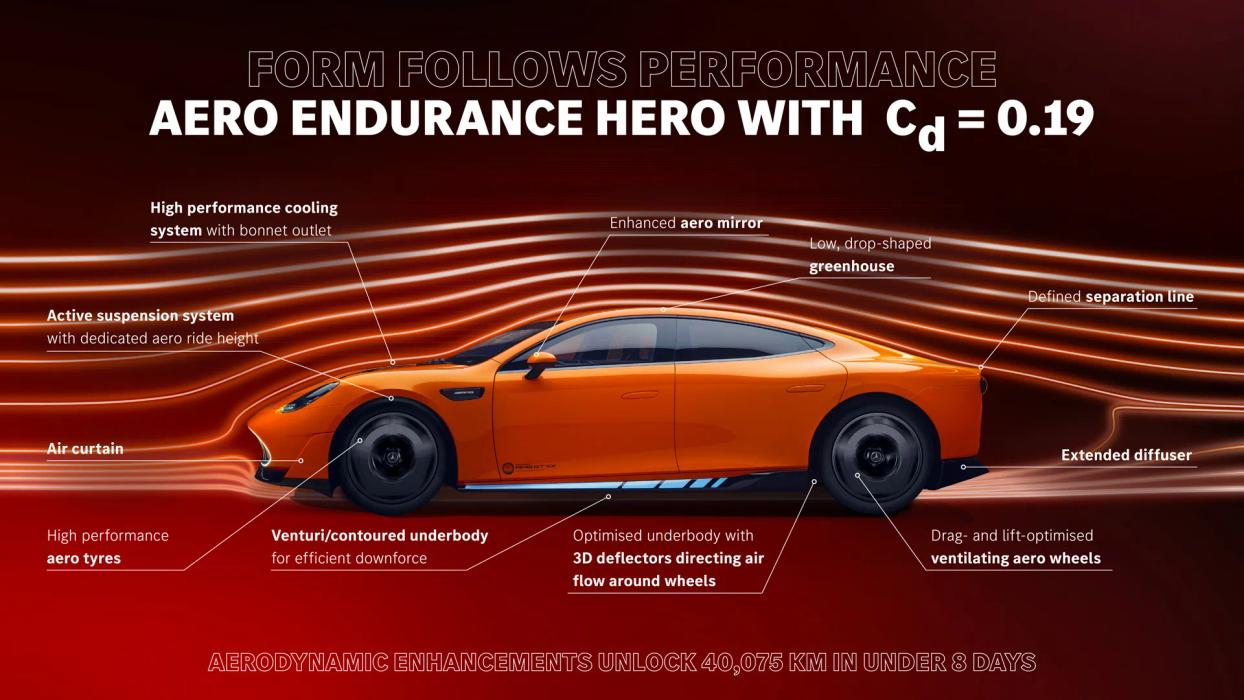

Optimised drag coefficient

Excellent cd value due to elaborate individual measures

Focused work on numerous details – such as optimized aero-mirrors, an extended diffuser, or the rear spoiler lip – further enhanced the aerodynamics of the CONCEPT AMG GT XX. During the extreme endurance test in Nardò, the Cd was only 0.19, despite its wide high-performance tires.

The active rear spoiler remained retracted during the extreme test, as the vehicle’s sophisticated aerodynamics already generated sufficient downforce. The key lies in the Venturi effect, created by a specially developed underbody contour. This reduces rear-axle lift with minimal impact on the Cd value, providing extremely high driving stability.

Furthermore, the completely new developed 20-inch wheels offer the ideal compromise between high driving stability and low air resistance. The aero-carbon cladding used for the aluminium wheels channel the air at the front axle from the outside to the inside, while at the rear axle, the air is pumped from the inside to the outside. This improves the airflow around the vehicle and offers superior driving stability with lower air resistance compared with fully closed wheels.

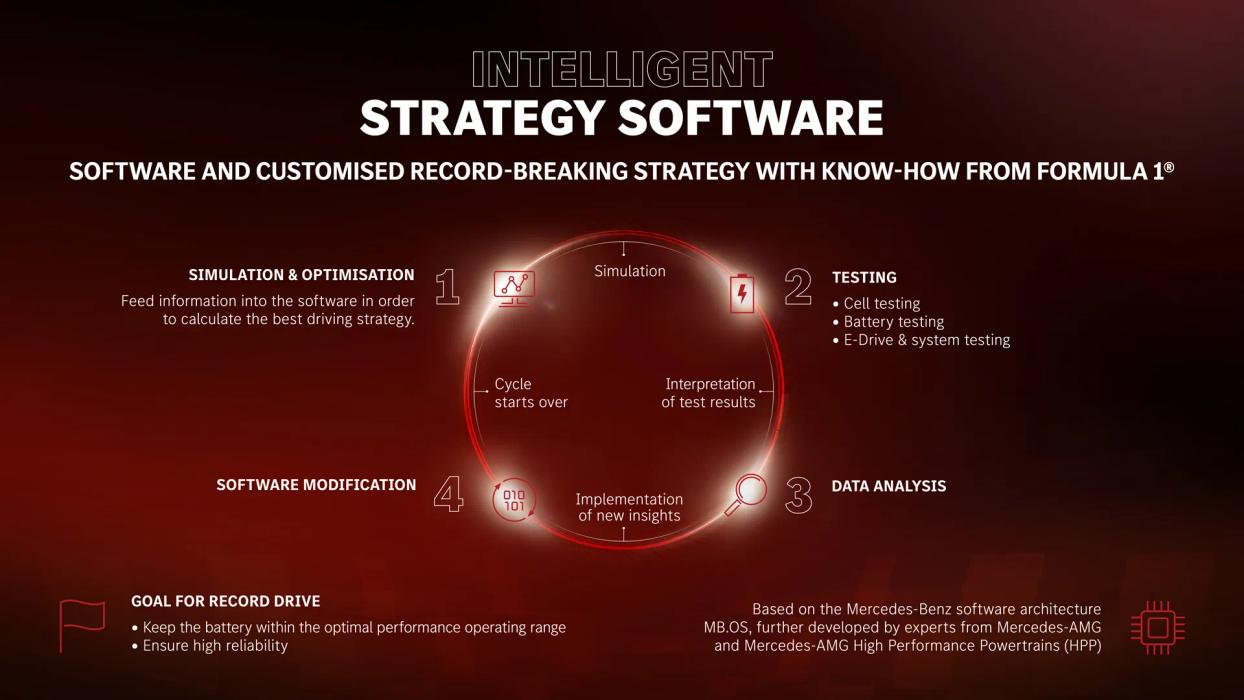

Intelligent software

Battery always in the optimal performance window

To develop an intelligent operating strategy, including battery management, expertise from Formula 1® was leveraged – overcoming a major challenge. To understand how battery cells behave under load, the development team initially used special reference electrodes.

The collected data was then integrated into the Battery Management System (BMS) software. This not only further optimized charging performance, but also enabled the software, via “virtual sensors” – since the internal process of individual battery cells cannot be measured directly – to simulate a view into the core of the battery cells throughout the entire drive.

The result: the creation of the optimal strategy for the endurance run. This included, for example, defining the ideal driving speed of 300 km/h, which offered the best balance of speed and efficiency. During the test, the CONCEPT AMG GT XX accelerated to this target speed and held it for a pre-calculated number of laps, before engaging up to 0.6 g of recuperation for deceleration and feeding energy back into the battery. This ensured the vehicle to enter the pit at the optimal speed, coming to a precise stop at the charging station.